First-in / First-out

Equipped with roller conveyors for convenient single drum loading. Our warming ovens are equipped to customer specification and can be used in all industrial...

Drum Heating cabinet and container warming oven

Drum Heating cabinet and container warming oven

Dryer and tempering oven

Dryer and tempering oven

Heated agitator vessel and melting equipment

Heated agitator vessel and melting equipment

Drum Heater

Drum Heater

Pharmaceutical dryer and laboratory oven

Pharmaceutical dryer and laboratory oven

Heating jacket for IBC containers and vessels

Heating jacket for IBC containers and vessels

Drying system in nuclear technology

Drying system in nuclear technology

Hochtemperaturanwendung & Sonderheizung

Hochtemperaturanwendung & Sonderheizung

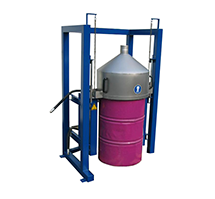

Lifting and tilting equipment

Lifting and tilting equipment

Air purification and transfer station

Air purification and transfer station

Drum fitting and Accessories

Drum fitting and Accessories

Immersion heater

Immersion heater

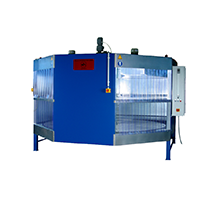

This hot water heating cabinet with a turntable for 4 drums is used for the gentle melting of temperature critical raw materials.

The turntable moves backwards and forwards, with the drums standing up, so that the unmelted centre of the drum is moved to the melted material at the edge.

->quick melting at low temperatures!

First-in - first-out system with rollerways for 36 drums

This cabinet is built in two segments for shipping and erection in China. Each rollerway lane is capable of 12 drums.

For the heated storage of drums and IBC containers in buildings or outside are these heating cabinets ideal.

These cabinets offer a large storage capacity using only a smahl footprint aerea. With an own weather protection roof or by using an existing shelter at site they can be placed outside and make it easy to store material free of freezing or even at higher temperatures. Hot water, steam or electricity are the most common heating sources.

An automatic controlled chain conveyor is mounted into a EX steam heated cabinet with vertical door for the heating of 10 IBC containers on pallets.

The need of 10.000 kg heated raw material per each batch makes a large preheating facility neccessary. The quick loading and deloading by only one operator is possible by the use of the automatic chain conveyor and the driven vertical door.

An automatic controlled chain conveyor is mounted into a EX steam heated cabinet with vertical door for the heating of 10 IBC containers on pallets.

The need of 10.000 kg heated raw material per each batch makes a large preheating facility neccessary. The quick loading and deloading by only one operator is possible by the use of the automatic chain conveyor and the driven vertical door.

Heating cabinet with steam heating coil and air circulation in ATEX

version for heating and melting of raw materials.

Construction completely in stainless steel 1.4571 (SS 316) with collector basins and pumping tubes for direct connection of the IBCs to the pumping line. High sub construction for fitting into an existing production plant.

Heating cabinet with steam heating coil and air circulation and an integrated collecting basin with outlet:

The cold drums without lids are placed on top of the grids above the basin. The material in the drums is melted and drops down into the basin which is also heated by steam passing through tubes mounted on the rear side. The liquid material can be pumped to following processes when it is needed.

Wenn Sie Fragen zu unseren Produkten haben oder weiteres Informationsmaterial benötigen, dann kontaktieren Sie Ihren Ansprechpartner:

If you want more informations please contact our contact person: