Our industrial ovens for a wide range of different tasks

Our driers and tempering ovens are special circulating air ovens which can be adapted to a wide range of different tasks using different designs and equipment.

Drum Heating cabinet and container warming oven

Drum Heating cabinet and container warming oven

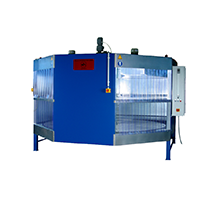

Dryer and tempering oven

Dryer and tempering oven

Heated agitator vessel and melting equipment

Heated agitator vessel and melting equipment

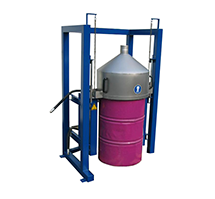

Drum Heater

Drum Heater

Pharmaceutical dryer and laboratory oven

Pharmaceutical dryer and laboratory oven

Heating jacket for IBC containers and vessels

Heating jacket for IBC containers and vessels

Drying system in nuclear technology

Drying system in nuclear technology

Hochtemperaturanwendung & Sonderheizung

Hochtemperaturanwendung & Sonderheizung

Lifting and tilting equipment

Lifting and tilting equipment

Air purification and transfer station

Air purification and transfer station

Drum fitting and Accessories

Drum fitting and Accessories

Immersion heater

Immersion heater

This electric heated dryier is stainless coated inside and is used to dry the vacuum insulation of vessels for liquid hydrogen.

The characteristics of this oven are the large doors on both sides for easy access and the throughlets for supply and vacuum lines. The control system is equipped with a programmer and a chart recorder.

If you want more informations please contact our contact person: