Assembly:

- Indoors, or outdoors with a weather-proof shelter

- Outside of explosion danger zones or with Explosion-proofing

Construction:

- Welded frame (very robust industry construction with minimized

- heat transfer through special outer profiles)

- Double frame with customised heat insulation

- heat isolation

Materials:

Frame, Sheeting and Fiitings

- Galvanized steel St. 37

- Stainless steel W.-Nr.: 1.4301 or 1.4571

- Aluminum

- other materials implemented on request

Heating:

- Customised and therefore economical heating system

- Heat source: Electicity, Steam, Hot water, Thermal oil

Air Circulation:

The air inside the heating cabinet is sucked upwards by the ventilator and directed through a hose over the radiators so that the heated air re-enters the bottom of the chamber and heats the drums continuously. The air circulation can be set for gentle or high-speed air flow, and includes an energy-saving heating option. Optimised air current pipes, the wide distribution of intaken air and a high performance ventilator optimally adjusted for volume and total air pressure ensure a highly effective, fast and even intake of warmth.

Controls:

- Thermostats, electric regulators, timers, program regulators, SPS controls

Data collection:

- Colour printer

- Filing and modelling software

- Connection to server

Fittings for steam heaters:

Hand-operated vents, Nominal value control, Safety temperature control, Condensation trap

Dangerous gas disposal:

- directed air suction/circulation systems

- direct drum-vaccuuming

- N2 (=Nitrogen) influx

Air circulation / Air extraction:

A flap system in the air hose allows for two modes for air direction:

- Air circulation: The fresh air valve remains closed, and the air inside the chamber is directed over the radiators as pure circulation air without added air intake. The result is energy-conserving, fast heating without loss of air

- Air extraction: Before opening the charging door the flap in the air hose can be manually switched over so that the ventilator presses the air inside the container through the waste air valve. At the same time fresh air from outside is sucked through the fresh air valve. Hot steam and evaporated gases are removed from the container, an added safety precaution for the operator. In addition a suction pipe with corresponding filters can be fixed to the waste air valve.

Loading:

- Caster rollers

- Charging trolley

- Retractable grids

- Bottomless container

- container with level base, tablars, etc.

Collector trays:

- Trays with drains/sump pumps

Other:

Breaker plates, Piping, Indicator adapter, Suction plug, Lighting, Weather shelter/ Roofing, Stainless steel models, Explosion-proofing, Level indicator, Leakage indicaor, etc.

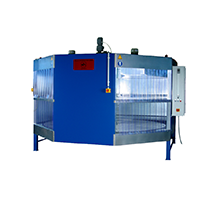

Drum Heating cabinet and container warming oven

Drum Heating cabinet and container warming oven

Dryer and tempering oven

Dryer and tempering oven

Heated agitator vessel and melting equipment

Heated agitator vessel and melting equipment

Drum Heater

Drum Heater

Pharmaceutical dryer and laboratory oven

Pharmaceutical dryer and laboratory oven

Heating jacket for IBC containers and vessels

Heating jacket for IBC containers and vessels

Drying system in nuclear technology

Drying system in nuclear technology

Hochtemperaturanwendung & Sonderheizung

Hochtemperaturanwendung & Sonderheizung

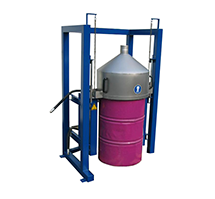

Lifting and tilting equipment

Lifting and tilting equipment

Air purification and transfer station

Air purification and transfer station

Drum fitting and Accessories

Drum fitting and Accessories

Immersion heater

Immersion heater