Melting container with steam-filled double shell

This container is used to melt food fats which can then be further processed after they have been tipped into dosing buckets.

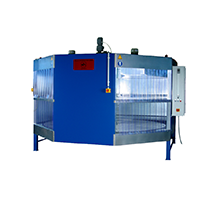

Drum Heating cabinet and container warming oven

Drum Heating cabinet and container warming oven

Dryer and tempering oven

Dryer and tempering oven

Heated agitator vessel and melting equipment

Heated agitator vessel and melting equipment

Drum Heater

Drum Heater

Pharmaceutical dryer and laboratory oven

Pharmaceutical dryer and laboratory oven

Heating jacket for IBC containers and vessels

Heating jacket for IBC containers and vessels

Drying system in nuclear technology

Drying system in nuclear technology

Hochtemperaturanwendung & Sonderheizung

Hochtemperaturanwendung & Sonderheizung

Lifting and tilting equipment

Lifting and tilting equipment

Air purification and transfer station

Air purification and transfer station

Drum fitting and Accessories

Drum fitting and Accessories

Immersion heater

Immersion heater

Rapid melting of loose materials (pellets, flakes or granulates), also with the addition and mixing of liquids or additives, is a preferred application field for ourmelting equipment:

Assuming a modular series with capacities of between 50 and 1,000 lwe can adapt the equipment to exactly suit your special application and recipe down to the last detail:

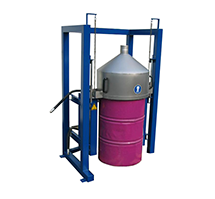

For melting and automatic distribution of large volumes of high-viscosity materials from drums or other transfer packagings we have developed the combination of melting out (heating jacket or warming oven), heated buffer volume and transport heating unit (vessel or heated pipework).

The opened, full containers standing on their end are quickly melted at the edge using warm circulating air or heating jackets so that the contents can slide into the receptacle located underneath. Melting grids can be used to accelerate the process.

In the heated buffer receptacle the material is liquefied completely and can then be fed to the process using either transfer vessels or pumps and pipework.

These melting units can be automated for the most part and are used by many of our renowned clients. We can also offer complete solutions including handling equipment for opening and tilting the drums or transfer vessels.

Product examples can be found at: Heated agitator vessels & melting equipment.

Use by requests our Contactform.