First-in / First-out

Equipped with roller conveyors for convenient single drum loading. Our warming ovens are equipped to customer specification and can be used in all industrial...

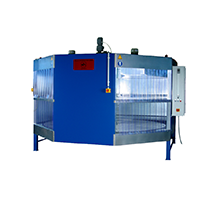

Drum Heating cabinet and container warming oven

Drum Heating cabinet and container warming oven

Dryer and tempering oven

Dryer and tempering oven

Heated agitator vessel and melting equipment

Heated agitator vessel and melting equipment

Drum Heater

Drum Heater

Pharmaceutical dryer and laboratory oven

Pharmaceutical dryer and laboratory oven

Heating jacket for IBC containers and vessels

Heating jacket for IBC containers and vessels

Drying system in nuclear technology

Drying system in nuclear technology

Hochtemperaturanwendung & Sonderheizung

Hochtemperaturanwendung & Sonderheizung

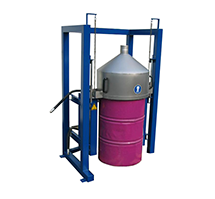

Lifting and tilting equipment

Lifting and tilting equipment

Air purification and transfer station

Air purification and transfer station

Drum fitting and Accessories

Drum fitting and Accessories

Immersion heater

Immersion heater

Warming ovens (WO) are used in all areas of industry with material treatment through preheating, heating, melting or maintaining a constant temperature.

We can equip these ovens to customer specification. They are characterised by a very durable and extraordinarily effective and energy-saving design. Depending on the heating medium, these warming ovens can be used up to 300°C, special electric or gas-heated versions from 300 to 500°C. However, the largest range of uses lies at temperatures from 60 – 130°C. The ovens are each designed optimised for the required process.

The sizes can range from small warming ovens for 1 – 2 drums to medium sizes for 2 – 4 Euro or chemicals pallets through to large hot storage units for up to 72 IBC/CP pallet slots on up to three levels.

Options: EX protection, stainless steel interior or complete stainless steel fit out, containment trays, different storage levels on top of each other, roller conveyors, air extraction systems, side hinged doors, sliding doors or rolling shutter doors and vertical-lift doors, floor level loading, shelving installations and much more… .

The ovens are optionally heated with steam, thermal oil or electrical resistance heaters; although combinations of different heating systems are also possible, e.g. for summer and winter operation. We can also install indirect gas heaters with burners and U-tube heat exchangers for air heating.

In all types of heating, high-performance fans together with optimised air ducts and air turning vanes ensure good removal of the heat by the heat exchangers or by the surfaces of the electric radiators.

Turbulent air flow in the interior via large air injection and directed air flow are essential for optimum and fast heat input into the drums and containers.

Product examples can be found at Drum- & container warming ovens.

Use by requests our Contactform.

If you want more informations please contact our contact person: